Carbon Black N220 N330 N550 N660

Carbon Black N660TYPEN219, N220, N234, N326, N330, N339, N472, N539, N550, N660, N772, N774PRODUCT INTRODUCTION OF N-6601. Package1.1 The packages of 20Kgs, which were made of PP material or Kraft papers.1.2 The packages of 500kgs /1000kgs, which were made of PP material1.3 Special specifications on......

Send Inquiry

Product Description

Carbon Black N660

TYPE

N219, N220, N234, N326, N330, N339, N472, N539, N550, N660, N772, N774

PRODUCT INTRODUCTION OF N-660

1. Package

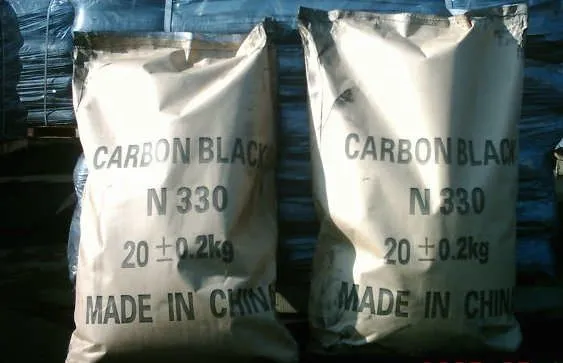

1.1 The packages of 20Kgs, which were made of PP material or Kraft papers.

1.2 The packages of 500kgs /1000kgs, which were made of PP material

1.3 Special specifications on the package are acceptable.

2. The Physical & Chemical property.

Grainy black amorphous solids, odorless, specific weight 1.82, burning point beyond 400° C, water insoluble, non-poisonous, stable chemical property.

3. The Perniciousness of carbon-black.

Nonflammable, explosibility, corrosive, toxicant, radioactive, dangerous nature.

4. Production standards.

We strictly fulfill the National Standard GB3778-2003 to produce rubber used carbon-black

5. Application.

It is used as the Strengthening agents and the filling agents for the production of Cord layer of tires, inner tubes, bicycle tires, rubber tubes, rubber tapes, cable ropes, shoes kind, and patterns.

6. Function

N660 fits for all kinds of rubber. Compared with half-reinforcing carbon-black, N660 has more complicated structure, smaller particles, and higher disperstiveness. The tensile strength, the tear resistance, and the tensile stress at a given elongation of vulcanized rubber are very high. Deformed little, heat rise slowly, well elasticity and good flex resistance, but the tensile stretch is low

TYPE

N219, N220, N234, N326, N330, N339, N472, N539, N550, N660, N772, N774

PRODUCT INTRODUCTION OF N-660

1. Package

1.1 The packages of 20Kgs, which were made of PP material or Kraft papers.

1.2 The packages of 500kgs /1000kgs, which were made of PP material

1.3 Special specifications on the package are acceptable.

2. The Physical & Chemical property.

Grainy black amorphous solids, odorless, specific weight 1.82, burning point beyond 400° C, water insoluble, non-poisonous, stable chemical property.

3. The Perniciousness of carbon-black.

Nonflammable, explosibility, corrosive, toxicant, radioactive, dangerous nature.

4. Production standards.

We strictly fulfill the National Standard GB3778-2003 to produce rubber used carbon-black

5. Application.

It is used as the Strengthening agents and the filling agents for the production of Cord layer of tires, inner tubes, bicycle tires, rubber tubes, rubber tapes, cable ropes, shoes kind, and patterns.

6. Function

N660 fits for all kinds of rubber. Compared with half-reinforcing carbon-black, N660 has more complicated structure, smaller particles, and higher disperstiveness. The tensile strength, the tear resistance, and the tensile stress at a given elongation of vulcanized rubber are very high. Deformed little, heat rise slowly, well elasticity and good flex resistance, but the tensile stretch is low

| Carbon black Executive Standard : GB3778 | ||||||||

| Items of Test | N220 | N326 | N330 | N339 | N375 | N550 | N660 | N774 |

| Iodine Absorption g/kg | 121±7 | 82±6 | 82±6 | 90±6 | 90±6 | 43±5 | 36±5 | 29±5 |

| DBP Absorption 10 -5 m 3 /kg | 114±6 | 72±6 | 102±6 | 120±7 | 114±6 | 121±7 | 90±5 | 72±5 |

| CDBP Absorption 10 -5 m 3 /kg | 92~104 | 62~74 | 82~94 | 93~105 | 90~102 | 80~90 | 69~79 | 58~68 |

| CTAB Adsorption Surface Area 10 3 m 2 /kg | 103~117 | 74~86 | 73~85 | 86~98 | 89~101 | 36~48 | 31~43 | 26~38 |

| Surface Area 10 3 m 2 /kg | 99~113 | 70~82 | 69~81 | 82~94 | 85~97 | 34~44 | 29~39 | 24~34 |

| Total Surface Area 10 3 m 2 /kg | 107~121 | 72~84 | 72~84 | 85~97 | 86@100 | 35~45 | 30~40 | 25~35 |

| Pigmentation Intensity % | 108~124 | 103~119 | 96`112 | 103~119 | 107~121 | ------- | ------- | -------- |

| Heating Loss ≤% | 2.5 | 2 | 2 | 2 | 2 | 1.5 | 1.5 | 1.5 |

| Ash ≤% | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 |

| Fine powder content ≤% | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| 45μm Sieve Residue ≤mg/kg | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 |

| 500μm Sieve Residue ≤mg/kg | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| Impurity | None | None | None | None | None | None | None | None |

| Pumping Density kg/m 3 | 355±40 | 455±40 | 380±40 | 345±40 | 345±40 | 360±40 | 440±40 | 490±40 |

| 300% Elongation Stress Mpa | -1.9±1.5 | -3.5±1.5 | -0.5±1.5 | 1.0±1.5 | 0.5±1.5 | -0.5±1.5 | -2.2±1.5 | -3.7±1.5 |

Related Category

Send Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.